Unveiling the Artistry of Jacquards, Dobbys, and Diverse Weaves with a Touch of Quality Perfection at Every Stage in Our Factory.

Weaving

Capacity

-

3.6 Million Meters per year

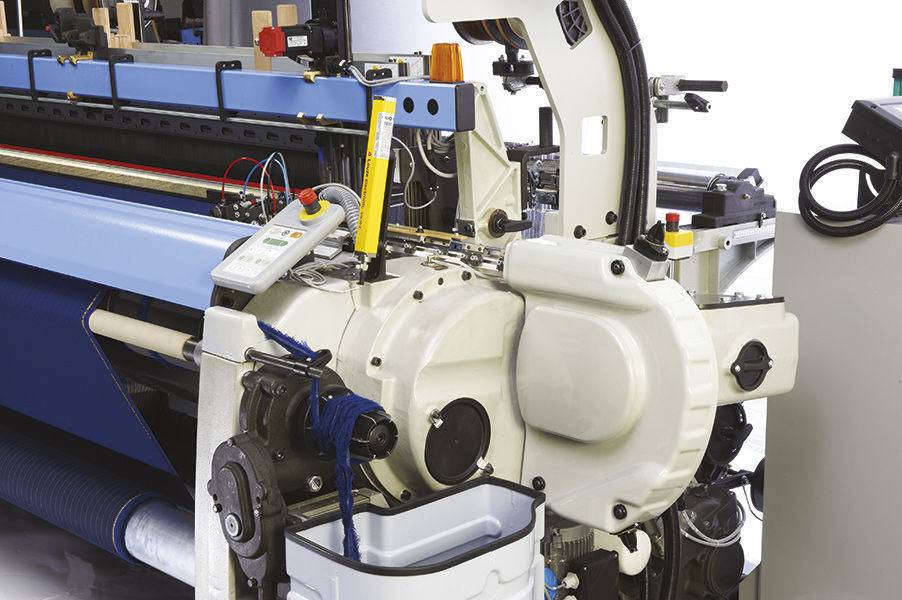

Equipment

-

72 shuttle-less Italian Rapier looms including Dobby, Wide Width (330 cm) and Jacquard types from the Itema-Somet group that can handle counts ranging from 0.5 Nm to 90 Nm.

-

3 Warping machines from Prashant Gamatex

-

3 Handlooms for sampling Pitlooms

-

All the finished fabrics are checked as per the 4.0 AQL system

-

The latest Captive Roof Top Solar Installation sources 16% of the energy used by the unit, the legal maximum as per the state regulations

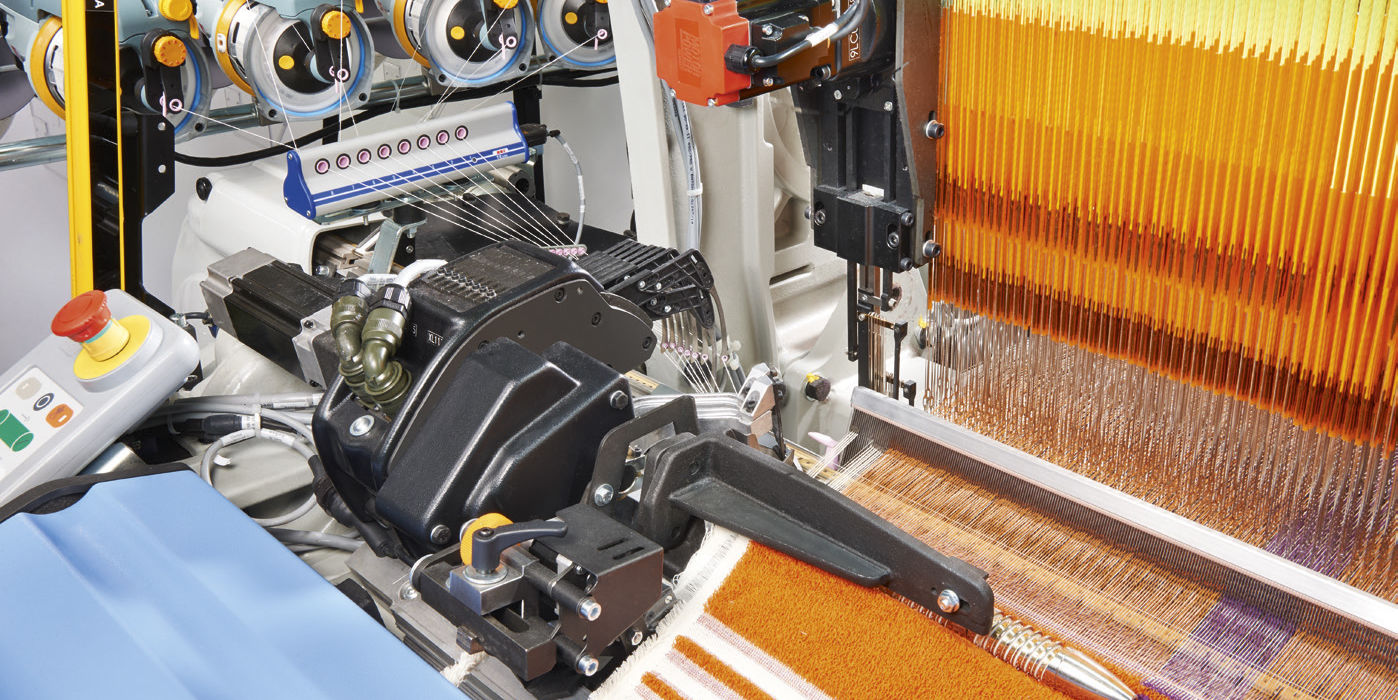

CUTTING EDGE HIGH-PRECISION

LOOMS WITH IoT

Latest Itema Italian Rapiers runs with the best in class dobbies, grippers and feeders.

IOT: third-party sensors on all looms installed to get a plant-level picture of the machine, RM and weaver efficiency. Online reporting and analysis for each variable.

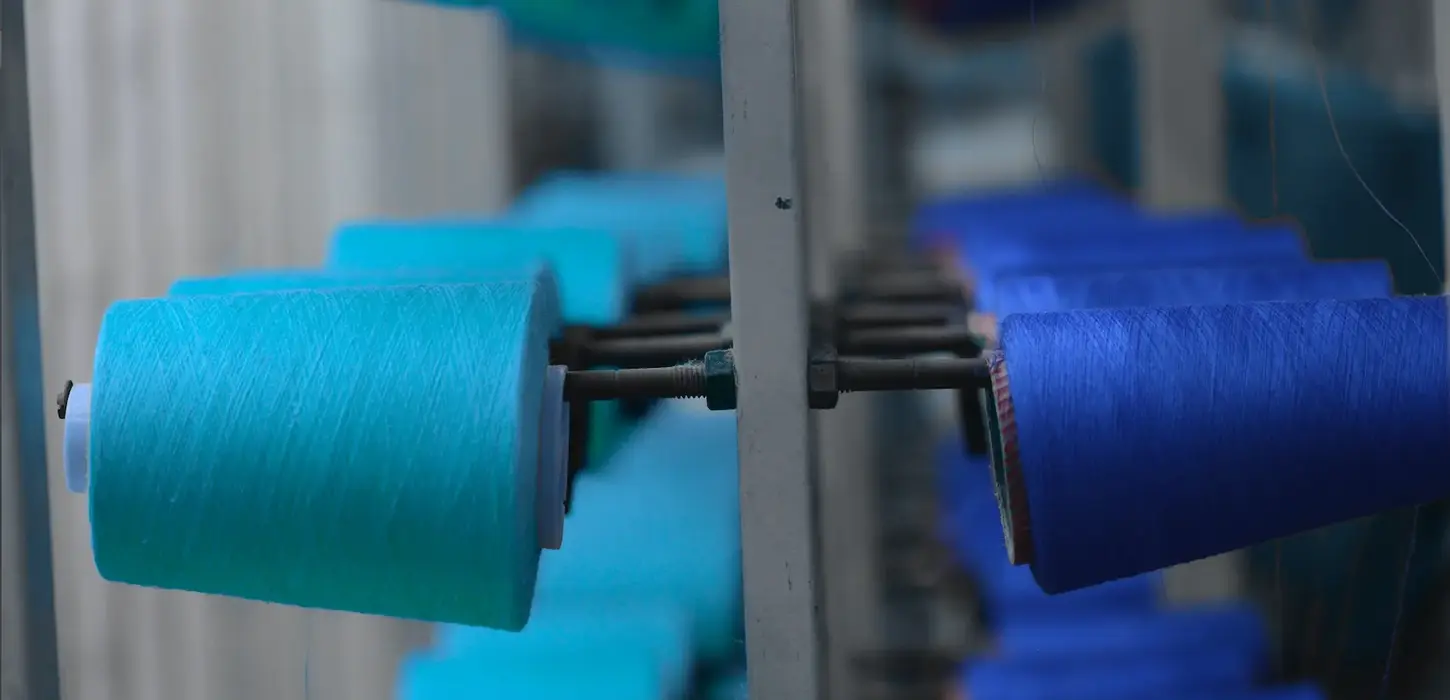

INCOMING YARN

INSPECTION

RKM (Strength) and CV (Count Variation) checks ensure yarn compliance with customer specifications. This is done at the raw yarn and the dyed yarn stage.

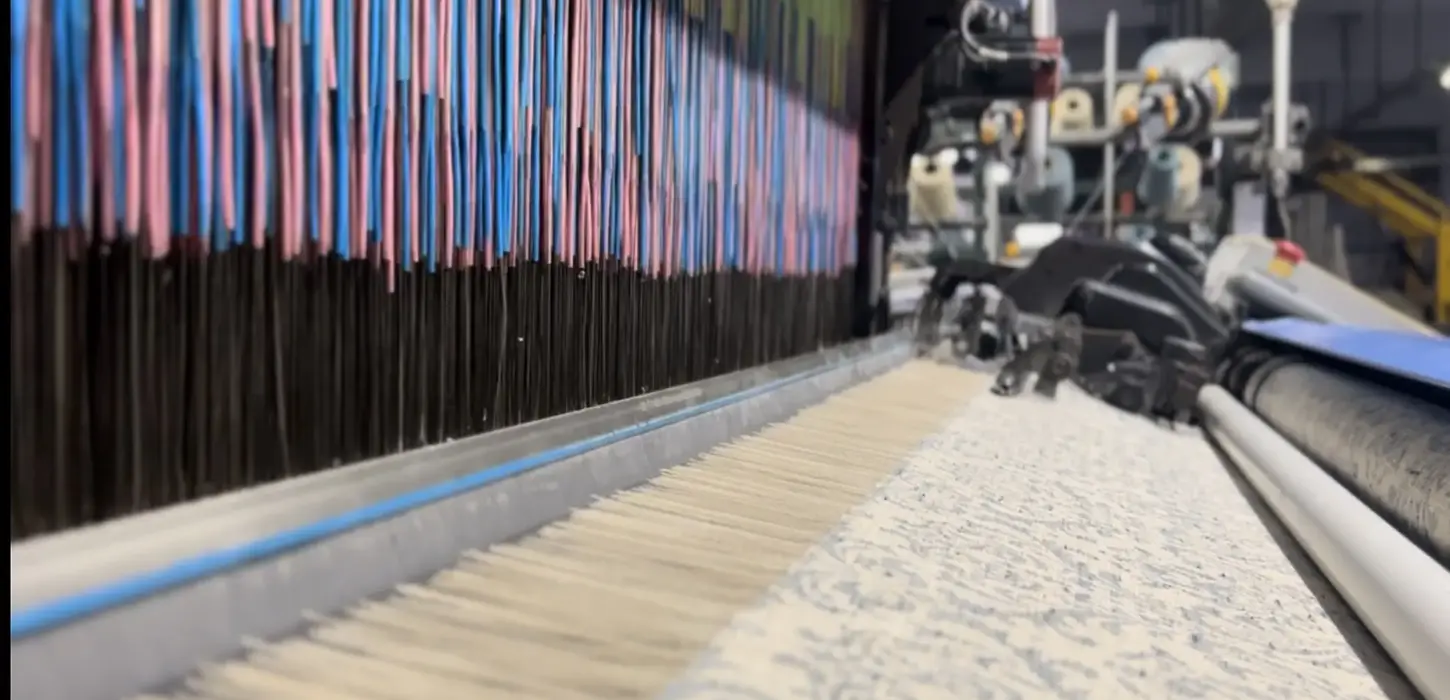

PRE-WEAVING AND

VERIFICATION

In house pit loom for crafting prototypes for customer to visualize bulk production.

The initial 10cm woven during the process is cross-verified with CAD, ensuring alignment with EPI/PPI/Width.

Quality Control

GREY (RAW FABRIC)

INSPECTION

Cloth is thoroughly inspected for weaving defects and is conducted on the gray inspection table.

FABRIC CHECKING AND

MENDING

The fabric undergoes width-wise checks using the AQL 4.0 system but since we’re dealing with premium fabrics, the goal is to get 100% cuttable fabrics. Therefore, in most cases, 100% of the fabric is taken through a mandatory mending route.

POST - PROCESSING QUALITY ASSURANCE

Digitized checking machines with touch screens and meter monitors to get a digital checking report of 100% of the fabrics. This is the third and final round of checks that each fabric goes through. Abrasion, GSM, and Pilling tests are conducted by our in-house lab to ensure superior quality. This is regularly audited by third-party tests also.